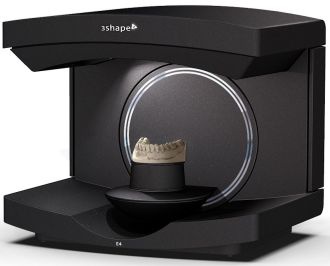

Features

Essilor Kappa chamfering

Thanks to the development of a new technology patented by Essilor, we invite you to rediscover chamfering. To obtain all the flexibility necessary for this delicate finishing task and guarantee an ultra-smooth chamfer.

Customized grooving

To obtain a high-quality finish, the automatic groove, which is calculated according to the shape and chamfer of the lens, now offers the guarantee of an impeccable fitting. If you want to customize your work and take the difficulty out of nylon-thread or metal-thread frames, the “customized” groove offers you the possibility of setting specific parameters for each groove, such as depth, width and position.

Whatever the type of groove you choose, everything is designed so that no fitting is impossible.

Shape modification, Large LCD display & Auto lens blocking

Equipped with the ability to alter shapes, the Essilor Kappa have a large built in TFT LCD screen on both edger and tracer to help you gain the highest precision in lens edging. The Kappa tracer is also equipped with the automatic lens blocking function, which makes blocking at ease with only a touch of a button.

High-Precision Tracing

For optimum fit of the lens in the frame, High-Precision Tracing® is a must. It defines the characteristics of the frame groove profile which will be crucial in the calculation of the dimensions of the finished lens.

With High-Precision Tracing®, the lens is impeccably fitted when it comes out of the machine, no need for further adjustment.

Shape memory and networking system

The Essilor Kappa has a memory of 200 shapes. You can work in a continual work stream or prepare your tracings in advance at the requisite moment. The Essilor Kappa is also capable of forming a network of a series of edgers to a single tracer which is suitable for laboratory setups.

There are no reviews yet.